Why MILKFISH?

- Hatchery technology for large-scale seed production is already established

- Easy to culture and can be grown in a wide range of environments

- Innovations in culture practices based on research data and farmer’s experiences have been adopted by industry practitioners

- An important food commodity in Southeast Asia

How to culture MILKFISH?

Broodstock management

- Milkfish takes about 3-5 years to attain sexual maturity and spawns under marine conditions.

- Milkfish can be grown to broodstock size (about 3-5 kg) in earthen ponds, in marine net cages, or in tanks

- For a start, about 100 juveniles can be stocked in a 1000 m2 pond, or 10 m diameter cage, or 200-ton tank.

- Growing juvenile milkfish to broodstock size for 3-4 years in brackishwater ponds relying mostly on natural pond productivity and occasional supplemental feeding when needed is more cost-effective than growing them in tanks or marine cages.

- Juveniles are given commercial feed twice a day at 2-3% of fish body weight until they reach broodstock size.

- After 3 years or when stocks begin to mature, potential breeders in ponds should be transferred to either concrete tanks or marine net cages.

Larval rearing

- Clean the larval rearing tanks (LRT) with detergent and thoroughly rinse with fresh water.

- Fill tanks to half the volume of LRT with filtered seawater a day before stocking the larvae to stabilize the condition of the rearing water.

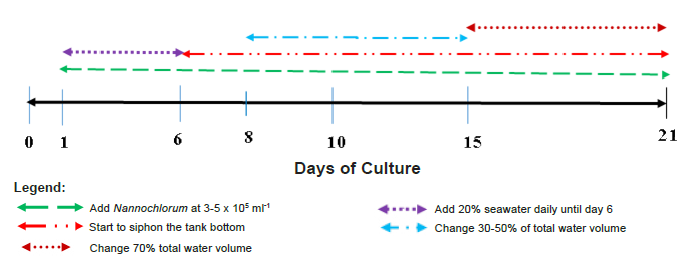

- Increase seawater level of the LRT daily following the protocol for water management (see Figure 1 below).

- Add Nannochloropsis sp. at 300,000–500,000 cells/ml daily.

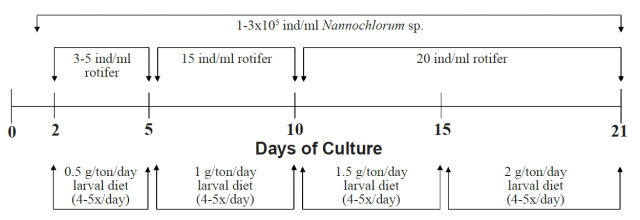

- Feed larvae with enriched rotifers (Brachionus sp.). The feeding ration is adjusted according to the age of milkfish larvae until day 15. Following the feeding scheme in Figure 2 will minimize the volume of rotifer needed for feeding the larvae during the early stage. Consumption of rotifer during the early larval stages is low and gradually increases as the larvae grow. The ration is increased to 20 ind/ml of rotifers starting day 16 until harvest. Adjust feeding rations when the survival of fry is high or when the rotifer density in the afternoon decreases according to the suggested daily feeding ration.

- Count the rotifer density in the morning and in the afternoon. If rotifer density falls below the desired ration add rotifer into the LRT.

- Introduce larval diet starting day 8 at 1 g/ton/day and increase ration to 2-3 g/ton/day as the larvae grow.

- Feeding should be done before 9 am to prevent starvation of the larvae/fry.

- Siphon the water out of the tanks starting on day 6 to remove excess food and debris. Practice early feeding of larvae before siphoning is done. Siphon the water out of the tanks every other day to minimize stress to the larvae.

- The rearing period of milkfish in the hatchery is 21-25 days. When the fry starts to swim in a circular motion inside the tank, this is an indication that the fry is ready for harvest.

- Harvesting of fry is done early in the morning, 1-2 days before the scheduled transport to have enough time for the milkfish fry to rest before transport.

Minimum and maximum levels of different water parameters that should be observed during larval rearing

| Water parameters | Minimum | Maximum |

| Temperature (°C) | 28 | 32 |

| Salinity (ppt) | 28 | 33 |

| Dissolved oxygen (mg/L) | 4 | Saturation |

| pH | 6 | 8 |

| Ammonia (mg/L) | <0.02 | |

| Nitrite (mg/L) | <0.01 | |

| Chlorine (mg/L) | <0.02 |

Cage culture operations

- Cages must be set up in calm waters to protect them from strong winds and waves. Ideal areas are coves, sheltered lagoons, inlet bay, or behind an island with adequate water flow. The site must also be free from harmful pollutants.

- Water depth should be at least 10 meters at the lowest low tide (ideally, 15-30 m) with good water exchange or flushing. The substrate of the site should be coarse or sandy and away from seagrass beds and coral reefs.

- Stock 12,000 pieces fingerlings in a 10 m x 10 m x 4 m cage.

- Hand-feed fingerlings at 8 am, 12 noon, and, 4 pm at the center of the cage (see table below for the feeding rates).

- Change the nets once a month or as the need arises to allow efficient water exchange.

- A partial harvest can be done when the fish reached the size of 400-500 grams.

Feeding rates

| Fish weight (g) | Rate (% of fish body weight) |

| 5-50 | 10 |

| 51-125 | 8 |

| 125-199 | 6 |

| 200-250 | 5.5 |

| 251-300 | 5 |

| 300-400 | 4 |

| 400-500 | 3.5-3 |

| >500 | 2.5 |

Suitable water quality for cage culture of milkfish

| Parameters | Range |

| pH | 7.5-8.3 |

| Dissolved oxygen | 4-8 mg/l (ppm) |

| Water salinity | 20-32 ppt |

| Water temperature | 26-32°C |

| Ammonia nitrogen | less than 0.02 mg/l |

| Water current | 0.1 m/second |

Is MILKFISH profitable?

Technical information in small-scale hatchery operations

| Project duration (years) | 10 |

| Rearing tanks, cubic meters | 10,000 |

| Number of tanks | 6 |

| Stocking density, number of larvae per liter | 15-25 |

| Number of larvae stocked in all 6 tanks per run | 1,200,000 |

| Larvae requirement per year | 12,000,000 |

| Survival rate of larvae, % | 50 |

| Number of fry harvested per run | 600,000 |

| Number of runs per year | 10 |

| Number of fry produced per year | 6,000,000 |

| Selling price, PhP per fry | 0.30 |

Cost and returns analysis of a small-scale hatchery operations (as of 2016)

| Quantity | Unit Cost | PhP/year | |

| Sale of fry per year, PhP 0.30 per piece, 3% mortality allowance as discount | 5,820,000 | 0.30 | 1,746,000 |

| Variable cost | |||

| Larvae stocked per year, PhP 12,000 per million | 12 | 12,000 | 144,000 |

| Feeds, kg | 750 | 10 | 7,500 |

| Fertilizers, kg | 600 | 10 | 6,000 |

| Other supplies | 700 | 10 | 7,000 |

| Electricity, 720 kwh/run, 10 runs/year | 7,200 | 10 | 72,000 |

| Fuel, 100 liters/month, PhP 50/liter | 1,200 | 50 | 60,000 |

| Labor | |||

| 1 technician, PhP 10,000/month, 13 months | 13 | 10,000 | 130,000 |

| 1 hatchery aide, PhP 10,000/month, 13 months | 13 | 6,000 | 78,000 |

| Harvest expenses @ PhP .01/fry | 60,000 | ||

| Maintenance, 2% of equipment | 7,500 | ||

| Consumable materials, plankton nets, filter bags | 5,000 | ||

| Subtotal | 577,000 | ||

| Fixed cost | |||

| Rent on land, PhP 1,500/month | 12 | 1,500 | 18,000 |

| Depreciation | 149,600 | ||

| Management overhead, PhP 10,000/month, 13 months |

13 | 10,000 | 130,000 |

| Business permit | 5,000 | ||

| Interest on loans to fund half of capital investment cost & all variable cost, 12% per annum, 12 months term |

120,300 | ||

| Opportunity cost of capital, 2.5% interest rate per annum | 10,638 | ||

| Subtotal | 433,538 | ||

| TOTAL COST | 1,010,538 | ||

| Net income per year | 711,943 | ||

| ROI % | 86% | ||

| Payback period | 0.96 | ||

| Unit cost (PhP/fry) | 0.17 |

Technical information for 1-cage and 4-cage operation

| Project duration (years) | 5 |

| Culture period (days; 120-150, average=135) | 135 |

| Cage size (10 m x 10 m x 5 m) | 500 |

| Stocking density (pcs/m3) | 30 |

| Number of fingerlings stocked per cage (pcs) | 15,000 |

| Number of fingerlings stocked in 4 cages (pcs) | 60,000 |

| Survival rate (%) | 95 |

| Number of milkfish at harvest per crop per cage (pcs) | 14,250 |

| Size at harvest (g) | 440 |

| Volume of harvest per crop (kg) | 6,270 |

| Number of cages | 4 |

| Volume of harvest from 4 cages, 1 crop (kg) | 25,080 |

| Number of crops per year | 2 |

| Volume of harvest from 4 cages per year (kg) | 50,160 |

| Farm-gate selling price of milkfish (400 g per piece) | 90 |

Costs-and-returns analysis of monoculture of milkfish in 1-cage and 4-cage operation (as of 2014)

| Price/unit (PhP) |

Units/ cage/ run |

1-cage Operation | 4-cage Operation | ||||

| PhP/cage/ run |

PhP/year | PhP/cage/ run |

PhP/run | PhP/year | |||

| Revenue | |||||||

| Gross sales, milkfish, 400 g per piece | 90 | 6,270 | 564,300 | 1,128,600 | 564,300 | 2,257,200 | 4,514,400 |

| Costs | |||||||

| A. Variable costs | |||||||

| Milkfish fingerlings | 6 | 15,000 | 90,000 | 180,000 | 90,000 | 360,000 | 720,000 |

| Feeds (starter), 25 kg/sack | 617 | 51 | 31,467 | 62,934 | 30,837 | 123,350.64 | 246,701 |

| Feeds (grower), 25 kg/sack | 732 | 192 | 140,544 | 281,088 | 137,733 | 550,932 | 1,101,864 |

| Feeds (finisher), 25 kg/sack, FCR=2.2 | 725 | 308 | 223,300 | 446,600 | 218,834 | 875,336 | 1,750,672 |

| Harvesting cost | 3,000 | 1 | 3,000 | 6,000 | 3,000 | 12,000 | 24,000 |

| 1 operator for 1 cage (1 hired aide + 1 operator for 4 cages) PhP 4,000/month each, 13 months |

4,000 | 13 | 26,000 | 52,000 | 13,000 | 52,000 | 104,000 |

| Maintenance and repairs (3% of investment costs per year if 1 cage, 2% if 4 cages) |

2,220 | 4,440 | 1,437.75 | 5,751 | 11,502 | ||

| Total variable costs | 516,531 | 1,033,062 | 494,843 | 1,979,370 | 3,958,740 | ||

| B. Fixed Cost | |||||||

| Depreciation costs | 24,200 | 48,400 | 23,660 | 94,640 | 189,280 | ||

| Business license & other permits, 4 cages, PhP 5000/year |

1,500 | 3,000 | 375 | 1,500 | 3,000 | ||

| Interest on loans to variable cost, 12% per annum, 4.5 months loan per term |

11,622 | 23,244 | 11,134 | 44,536 | 89,072 | ||

| Opportunity cost of own capital, 0.5- 2.5% interest/annum |

370 | 740 | 1,797 | 7,189 | 14,378 | ||

| Total fixed costs | 37,692 | 75,384 | 36,966 | 147,865 | 295,729 | ||

| TOTAL COSTS | 554,223 | 1,108,446 | 531,809 | 2,127,235 | 4,254,469 | ||

| Net income (PhP) = (gross revenue-total costs) | 10,077 | 20,154 | 32,491 | 129,965 | 259,930 | ||

| ROI (%) = (net income/investment cost) x 100 | 13.6% | 45.2% | |||||

| Payback period (years) = investment cost/(annual net income + annual depreciation) |

2.16 | 1.28 | |||||

| Unit variable cost | 82.38 | 78.92 | |||||

| Break-even price (PhP/kg) = annual total cost/ annual production |

88.39 | 84.82 | |||||

| Break-even production (kg) = total cost/selling price |

12,316 | 47,271.88 | |||||

Note: 2% discount on feed cost on bulk buying

References:

Reyes, O., Ayson, E. G., & Eullaran, B. (2016). Seed production of milkfish Chanos chanos Forsskal. Tigbauan, Iloilo, Philippines: Aquaculture Department, Southeast Asian Fisheries Development Center.

Reyes, O. S., de Jesus-Ayson, E. G. T., Eullaran, B. E., Corre Jr., V. L., & Ayson, F. G. (2015). Development and management of milkfish broodstock. Tigbauan, Iloilo, Philippines: Aquaculture Department, Southeast Asian Fisheries Development Center.

Gaitan, A. G., Toledo, J. D., Arnaiz, M. T., Ayson, E. G. D., Altamirano, J. P., Agbayani, R. F., … Marte, C. L. (2014). Milkfish Chanos chanos cage culture operations. Aquaculture Department, Southeast Asian Fisheries Development Center.

Need ASSISTANCE?

Watch related videos!

Milkfish Fry Collection, Handling, and Transport (Part 1)

Milkfish Fry Collection, Handling, and Transport (Part 2)

Get a copy of our manuals!

|

AEM 45 Fingerlings production of hatchery-reared milkfish (Chanos chanos) in earthen nursery ponds (2010) 32 pp EB Coniza et al. An extension manual detailing the three types of nurseries, site selection, and pond preparation; fry selection, handling, transport, acclimation and stocking, fish monitoring, feeding, and harvest; and economics. Each copy costs US$6 |

|

AEM 58 Milkfish Chanos chanos cage culture operations (2014) 39 pp Albert gaitan et al A 39-pages extension manual describing the biology, fingerling production, site selection, cage design and construction, measurement & analysis of water & sediment quality parameters, and economics. Each copy costs US$7 |

|

AEM 62 Development and Management of Milkfish Broodstock (2015) 33 pp Ofelia S. Reyes et al A 33-page manual detailing the methods/procedures in managing milkfish broodstock Each copy costs US$8 |

|

AEM 63 Seed Production of Milkfish Chanos chanos Forsskal (2016) 26 pp Ofelia Reyes, Bernardita Eullaran, Evelyn Grace Ayson A 26-page manual describing the site selection, hatchery design, spawning, larval rearing, natural food production, and economic analysis for milkfish. Each copy costs US$4 |

Check out our online bookstore for more titles: www.seafdec.org.ph/bookstore

Attend our hands-on training!

Marine fish hatchery operations training course at SEAFDEC/AQD’s Tigbauan Main Station.

|

| View training brochure |

To apply, kindly contact:

Training and Information Division

(63-33) 330 7030

training@seafdec.org.ph

Check out our training schedule: www.seafdec.org.ph/training

SEAFDEC/AQD Southeast Asian Fisheries Development Center | Aquaculture Department

SEAFDEC/AQD Southeast Asian Fisheries Development Center | Aquaculture Department